Walk-in coolers are a vital asset to convenience stores, ensuring that perishable items remain fresh, beverages stay chilled, and customers have access to the products they demand. However, like any piece of commercial equipment, walk-in coolers require regular and meticulous maintenance to perform effectively. Neglecting cooler maintenance can lead to mechanical failures, increased energy costs, and spoiled inventory—issues no convenience store owner can afford.

The Importance of Walk-In Cooler Maintenance

Walk-in coolers are significant investments, and their constant operation makes them prone to wear and tear. For convenience store owners, the repercussions of neglecting cooler maintenance go beyond financial losses; they also impact product integrity, customer satisfaction, and even energy consumption.

Here are three primary reasons routine maintenance is essential:

- Preventing Costly Repairs: Some cooler components, like compressors and fans, are expensive to replace. Regular upkeep helps identify small issues before they escalate into costly repairs or complete system failures.

- Preserving Product Quality: Spoiled or improperly stored inventory can lead to revenue losses and dissatisfied customers. Walk-in coolers must maintain consistent temperatures to extend the shelf life of perishables and beverages.

- Enhancing Energy Efficiency: A poorly maintained walk-in cooler can consume more energy than necessary, leading to surging utility bills. Clean and functioning components ensure optimal energy efficiency, saving operating costs in the long run.

Key Maintenance Areas for Walk-In Coolers

Maintenance of a walk-in cooler involves multiple components that require attention. Below, we detail the essential areas to focus on:

1. Cleaning the Coils

The condenser and evaporator coils play a pivotal role in regulating the cooler’s temperature. Over time, dust and debris can accumulate, reducing efficiency and straining the cooling system.

- Why it’s crucial: Dirty coils force the system to work harder, increasing energy consumption and the risk of breakdowns.

- Maintenance tip: Clean the coils every three months using a coil cleaning solution specifically designed for refrigeration equipment.

2. Inspecting and Replacing Seals

The gaskets and seals around the cooler door ensure an airtight seal to prevent warm air from entering. Damaged seals result in temperature fluctuations that can compromise stored products.

- Why it’s crucial: Poor sealing increases energy demand and risks inventory spoilage.

- Maintenance tip: Inspect seals monthly for any tears, cracks, or wear. Replace them as needed to maintain optimal performance.

3. Monitoring and Maintaining the Condensate Drain

Blocked or clogged drains can lead to water buildup, which not only affects the cooler’s efficiency but also creates a breeding ground for mold and bacteria.

- Why it’s crucial: Blockages can result in operational downtime and unsanitary conditions.

- Maintenance tip: Check and clean the condensate drain with a mix of bleach and water at least twice a year.

4. Checking the Thermostat

The thermostat regulates the cooler’s internal temperature. A malfunctioning thermostat may lead to inconsistent cooling, which can damage inventory.

- Why it’s crucial: Accurate temperature settings are vital for product safety and energy efficiency.

- Maintenance tip: Regularly calibrate the thermostat and ensure it matches the temperature reading on a separate thermometer.

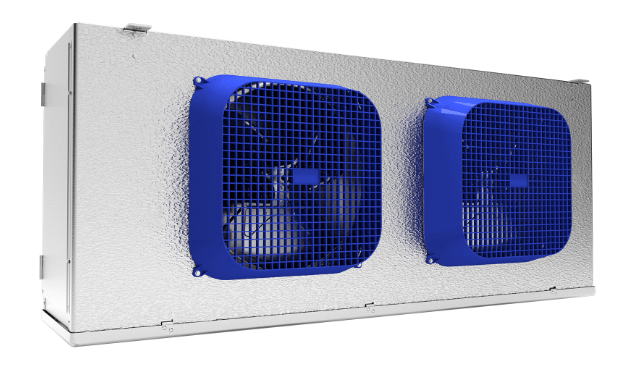

5. Fans and Motors

Fans circulate cold air throughout the cooler, while motors keep the entire unit running. These are high-wear components that must function optimally for effective cooling.

- Why it’s crucial: Faulty fans or motors can result in uneven cooling and reduced efficiency.

- Maintenance tip: Inspect fans and motors for unusual noises or wear during routine checks and lubricate moving parts if necessary.

6. Lighting

While lighting may not seem critical to cooler function, it plays a role in customer satisfaction when they access beer caves or self-service coolers.

- Why it’s crucial: Well-lit coolers make it easy for customers to locate items and improve the overall shopping experience.

- Maintenance tip: Use energy-efficient LED lighting and replace burnt-out bulbs promptly.

The Role of Professional Cooler Maintenance Services

While routine checks and cleaning can be performed by store staff, certain elements of walk-in cooler maintenance require professional expertise. Hiring a technician skilled in convenience store interior design and refrigeration systems, such as those from JayComp Development, ensures that even the most complex issues are detected and resolved efficiently.

Key benefits of professional services include:

- Advanced diagnostic tools to identify hidden problems.

- Expertise in handling refrigerants and system fluids.

- Compliance with safety and maintenance standards.

Additional Considerations for Specialized Coolers

For convenience stores with specialized coolers, such as commercial ice makers or beer caves, tailored maintenance is crucial. Here are a few tips:

- Commercial Ice Makers: Regularly sanitize the interior to prevent bacteria buildup and descale the unit according to the manufacturer’s recommendations.

- Beer Caves: Monitor shelving and layout to ensure optimal airflow and an evenly chilled environment. Consistent temperature control is paramount for beer quality.

- Convenience Store Interior Design: Collaborate with professionals like JayComp Development to optimize cooler placement and store layout. A well-designed space not only improves operational efficiency but also enhances the customer experience.

How a Well-Maintained Cooler Impacts Your Store

A well-maintained walk-in cooler reflects positively on your convenience store’s operations and reputation. Here are some of the long-term benefits:

- Improved Product Turnover: Proper cooling maintains the freshness and quality of inventory, encouraging higher sales and reducing waste.

- Enhanced Customer Experience: When customers can rely on consistently chilled products, they’re more likely to return.

- Regulatory Compliance: Many jurisdictions have strict guidelines for food storage. Regular maintenance helps you remain compliant with health and safety standards.

Start Maintaining Your Cooler Like a Pro

Taking proactive steps to maintain your walk-in cooler pays off in the long term by preventing breakdowns, lowering energy costs, and preserving the quality of your inventory. Convenience store owners can benefit from forming a partnership with a trusted provider like JayComp Development, who specializes in convenience store design, refrigeration systems, and related services.

Are you ready to optimize the performance of your walk-in cooler and other cooling systems? Contact JayComp Development today to discuss maintenance strategies and explore refrigeration solutions tailored to your needs.