Ensuring food safety is at the heart of every successful restaurant, catering business, or food service facility. When managing perishable inventory worth thousands of dollars, the last thing you want is an equipment failure—or worse, a health code violation. This is where compliant commercial walk-in coolers come into play.

Health and safety standards for food storage are stringent, and rightly so. Non-compliance not only puts your customers at risk but can also result in hefty fines, low inspection scores, or even business closure. This comprehensive guide will explain the key health and safety regulations that govern walk-in coolers and what you must do to ensure your units are compliant.

Why Health and Safety Compliance Matters

Proper storage of perishable goods is one of the most critical aspects of food safety. According to the Centers for Disease Control and Prevention (CDC), around 48 million Americans fall ill due to foodborne illnesses every year. Temperature abuse during storage is one of the leading causes, emphasizing the importance of commercial walk-in coolers in safeguarding food quality.

Failing to meet health and safety requirements can result in fines ranging from $100 to $5,000 per violation, depending on your jurisdiction. Worse yet, recurring non-compliance can lead to suspension or revocation of business licenses. Beyond legal ramifications, consider the reputational damage to your brand. Even a single food safety incident can deter loyal customers and tarnish trust.

Investing in health-compliant equipment, such as your walk-in cooler, is not just a regulatory necessity—it is a fundamental pillar of your overall food safety management system.

Regulatory Standards for Commercial Walk-In Coolers

Health and safety regulations for walk-in coolers vary by region, but there are universal standards to maintain. These regulations are often specified by organizations such as the FDA (U.S. Food and Drug Administration), USDA (United States Department of Agriculture), and local health departments. Here’s an outline of the key areas to address:

Temperature Regulations

- What the Law Requires

Health codes universally mandate that perishable food items be stored at temperatures below 40°F (4°C) to inhibit bacterial growth known as the “danger zone” (40–140°F or 4–60°C).

- Your Walk-In Cooler’s Role

Ensure your cooler consistently maintains temperatures within the safe range. Most units allow for multiple temperature set-points between 35–38°F for optimal conditions.

Insulation and Sealing Standards

- The Requirement

Walk-in coolers must have sturdy, well-insulated walls, floors, and doors to maintain internal temperature. States like California and Texas mandate thickness of 4 inches (R-value) as a requirement in foodservice storage.

- How to Check

Inspect door gaskets regularly, as they wear out faster than other components. Gaps or tears can lead to temperature inconsistency, affecting food safety.

NSF Certification

- Importance of Certifications

Certifications like NSF International (National Sanitation Foundation) indicate your equipment meets global hygiene and safety standards. This is often a minimum requirement for health code adherence in many jurisdictions.

Tip: Ask your supplier directly about certifications to ensure your units meet all local compliance needs.

Lighting and Material Safety Standards

- Food-Grade Materials

Ensure your cooler interior (walls, shelving) is made from easy-to-clean, corrosion-resistant materials, such as stainless steel or food-grade plastic.

- Shatterproof Lighting

Lighting compliance generally involves shatterproof lamps or protective covers to prevent contamination in the event of breakage.

Air Circulation and Ventilation

Proper ventilation ensures consistent temperatures across the cooler. Blocked vents or improper air circulation can lead to cold and hot spots, increasing spoilage risk.

Emergency Features

- Employee Safety

Regulations (including OSHA standards) require walk-in coolers to include emergency release mechanisms that prevent employees from being locked inside.

- High-Temperature Alerts

Many walk-in coolers now feature built-in alarm systems to notify you of rising temperatures, allowing quick intervention.

Tips for Maintaining Compliance

Once your equipment meets compliance standards, the next step is regular maintenance and inspection. Slowly accumulating wear and tear can jeopardize your unit’s ability to meet safety standards. Here’s how to stay compliant:

1. Scheduled Preventative Maintenance

Preventative maintenance ensures optimal functionality. Check condenser coils, door seals, and temperature controls at least quarterly.

2. Regular Calibration

Temperature control systems should be calibrated regularly to avoid any discrepancies in readings. Digital thermometers are often more accurate than analog systems.

3. Document Everything

Keep detailed records of maintenance checks, calibration, and inspections. Health inspectors often ask for documentation to verify compliance.

4. Monitor Performance with IoT

Smart monitoring systems track temperature in real time and send alerts when deviations occur. Investing in IoT-enabled walk-in coolers can help better manage compliance and minimize risks.

5. Training Your Staff

All employees should be trained on the importance of food storage protocols. Even the most advanced walk-in cooler cannot compensate for mishandling or improper storage practices.

Meeting Compliance with Modern Solutions

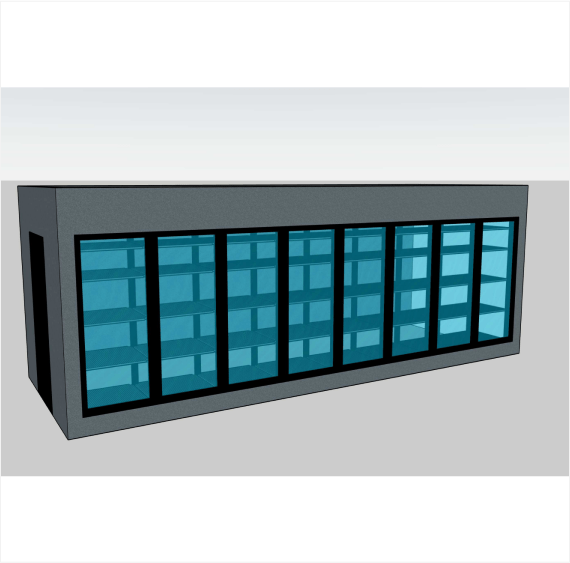

At JayComp Development, we take health and safety compliance seriously. All our commercial walk-in coolers are designed and manufactured to exceed industry standards. From durable insulation to automated temperature alarms, our units safeguard your perishable goods while ensuring you meet legal requirements.

Additionally, we include user-friendly tasting notes with every shipment, perfect for enhancing the customer experience. Whether you’re running a five-star restaurant or managing a food service facility, we specialize in providing solutions tailored to your unique needs.

Need help selecting a compliant cooler model? Contact one of our product specialists today. We’ll guide you through your options and provide a free quote.

Compliance is Key to Food Safety

Health and safety regulations are non-negotiable when it comes to running a successful food service operation. Ensuring that your commercial walk-in cooler complies with these regulations is essential for protecting both your customers and your business.

Routine monitoring, consistent maintenance, and choosing the right equipment will bring you one step closer to a safer, more reliable operation. Remember, a compliant walk-in cooler isn’t just a regulatory necessity—it’s an indispensable investment in the long-term reputation of your business.

Need expert advice or looking to upgrade? Explore our compliant, NSF-certified range of commercial walk-in coolers. Give your customers the confidence in the safety and quality they expect.